British scientists have invented a cheap flexible touch screen, and the cell phone is not afraid of breaking the screen.

According to foreign media reports Telegraph days ago, British scientists with silver and graphene as raw material, the invention of a flexible touch screen cheap.

At present, the touch screens on the market are very crisp, because they are usually made of indium tin oxide and covered with a layer of glass, so that when it falls to the ground, it will easily be smashed.

The indium tin oxide is not only fragile, but also difficult to prepare, which keeps the cost of maintaining the touch screen high.

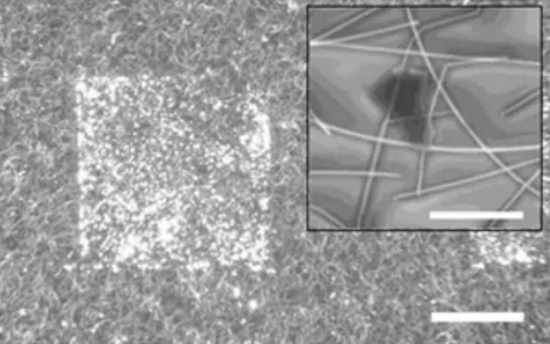

However, before the date of the University of Sussex (University of Sussex) the scientists found through research, we can make graphene - composed of a single layer of carbon atoms in a material - and silver nanowires with a conventional display screen generation and similar performance, and the manufacturing technology cost is only a conventional display manufacturing a small part of the cost.

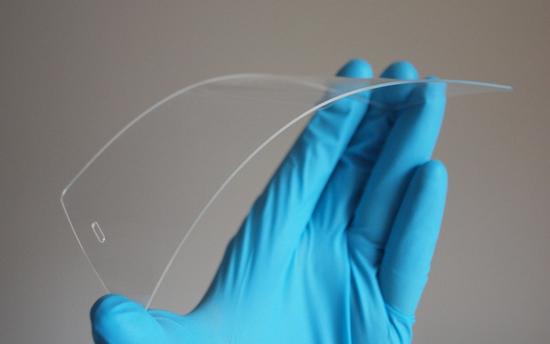

This material is also very flexible at the same time, so that it doesn't need a glass protective layer, which means that the top of the touchscreen can be replaced by some materials that are more easily bent and less damaged, such as plexiglass.

Dr. Matthew Raj led the study in the school of mathematics and physical sciences of the University of Sussex (Dr Matthew Large) said: "the touch screen on your mobile phone is so easy to be broken is mainly because of transparent conductive material using the touch sensor is indium tin oxide. This material is very fragile, so it needs a hard surface like glass to protect it.

"If your mobile phone dropped on a hard surface, or that you have your mobile phone accidentally broken, what is actually the glass layer. The material we developed does not need a hard glass surface, because the screen made of a mixture of silver nanowires and graphene is very flexible. "

"We will still need a protective layer, but it can be something more flexible than a glass. In this way, when you accidentally drop your smartphone to the ground, the screen of your cell phone will not be so fragile.

Although silver is also a rare metal, the difference between metal indium is that graphene can only be covered with the same area by mixing with very few components of silver. The amount of graphite needed to make graphene is very rich, so the cost of making this screen can be sharply reduced.

Scientists have found that they can float graphene atoms on the surface of water, pick them up with special tools, and then place them on top of silver nanowire film in any way, so as to finish the preparation of materials.

Alan Dalton, Professor of mathematics and physical science, University of Sussex, Professor Alan Dalton said: "with the help of sprinkler and rolling machine, we can easily integrate silver nanowires and graphene in this way. This means that the fragile phone screen will soon become a history. "

"The addition of graphene in the silver nanowires can also increase the conductivity of the screen material by about 10000 times the coefficient."

"This means that we can use a very small dose of silver to make the screen with the same level, or better performance. The screen made with this material can respond faster and consume less power. "

Dr. Rudge added, "this has paved the way for us to develop an arbitrary bending device one day." At present, the study has been published in the American Chemical Society Journal Langmuir.